Perlite Filter Aid

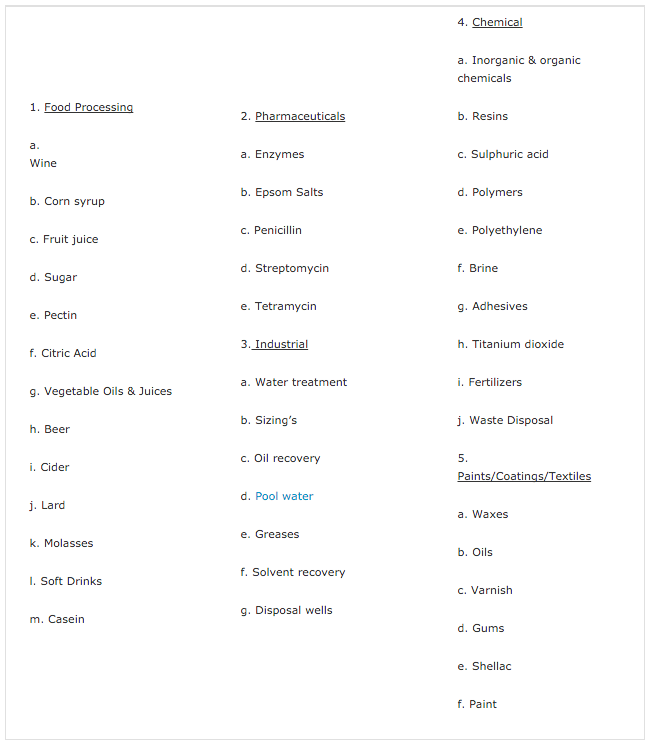

AUSPERL perlite filter aids are produced in a full range of grades to economically meet the flow rate and clarity requirements of almost every industry. Perlite is a generic name for a naturally occurring siliceous volcanic rock. A unique property of perlite is that it expands up to twenty times its original volume when it is heated to its softening range.

More….

This expansion process is caused by the presence of water in the crude rock. When perlite ore is rapidly heated to above 850c, this water vaporises and causes the softened rock to expand. Tiny glass like bubbles are produced which account for the light weight and exceptional physical properties of expanded perlite.

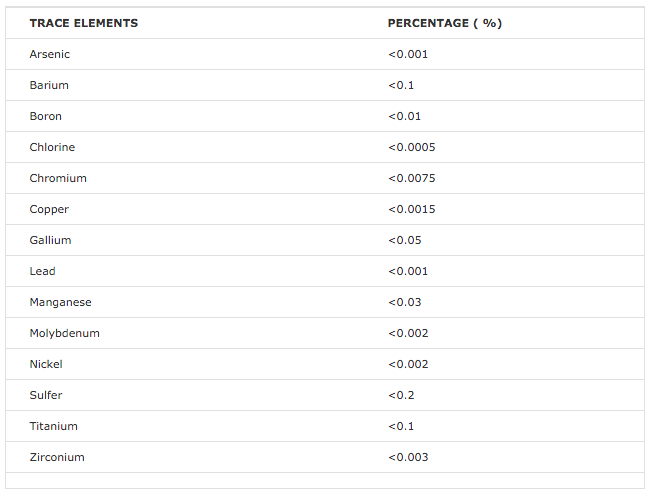

It is these light weight glasslike bubbles that are milled and classified under stringent quality control conditions to produce perlite filter aids. This material exhibits a unique, jagged interlocking structure with myriads of microscopic channels affording optimum flow rates and clarities for a wide variety of applications. Perlite filter aids do not impart taste, colour or odour to liquids being filtered and they are virtually insoluble in mineral and organic acids at all temperatures. Solubility in strong alkalis varies depending on temperature and contact time.

Australian Materials, Australian Processed

Cost advantage

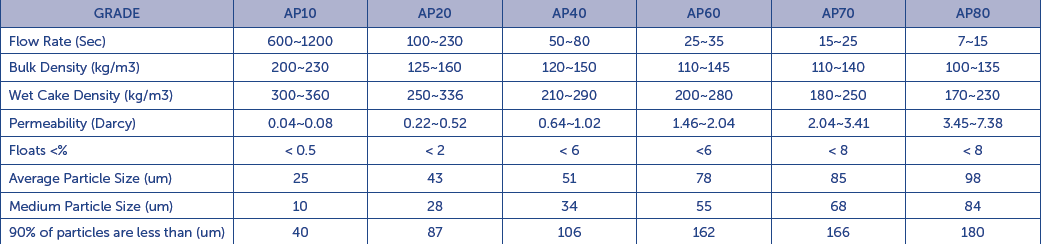

AUSPERL perlite filter cake density is 110-270kg/m3. The dry density of perlite filter aid ranges from 100-200kg/m3. Experience in a variety of applications in many industries has shown that users of filter aids can substantially reduce filtration costs without sacrificing performance by converting to perlite filter aid

Usable with standard equipment

High flow rates

Full range of grades

Grades produced are as follows:

Easy cake release

Inert-Codex approved

Use of spent filter cake

We would love to hear from you

Click below to get in touch with our friendly and experienced team.